Guide to Insulation Piercing Connectors

Guide To Insulation Piercing Connectors

An insulation-piercing connector is a type of electrical connector that utilises a connection process to pierce or displace the insulation of a wire or cable to make a conductive path with the conductor inside. They are also commonly known as insulation piercing clips, insulation displacement connectors and wire taps. Using an insulation piercing connector bypasses the need to strip a conductor of insulation before making a connection. Below we explain the common types available and offer the advantages and disadvantages of using such insulation piercing connectors.

1 - What is an Insulation Piercing Connector?

2 - Insulation Piercing Connector performance and reliability

6 - Conclusion: Insulation Piercing Probes

1 - What is an Insulation Piercing Connector?

Insulation Piercing connectors are purpose built for diagnosing, testing or connecting to wires in circuit quickly, with a minimum of fuss, where the terminal connection is in hard to reach area or its unsuitable to disconnect. They are available in various sizes, contact types and connection forms and using them during electrical testing is fast, efficient and dependable, as it doesn’t involve any wire stripping or twisting. The fast installation and minimum clean up combined with dependable performance have made insulation piercing connectors popular in many industries. Example electrical testing applications include; vehicle wiring looms, electronic locks, alarms, network and telecoms cables. These low voltage circuits are ideal for insulation piercing connectors.

2 - Insulation Piercing Connector Performance and Reliability

Connectors with insulation piercing technology are designed to create a semi-permanent metal to metal connection between the wire conductor and the insulation piercing connector. There are a nunber of factors that affect their performance and the reliability of the connection. These include:

- The type of contact

- Method of connection

- Connector tip design

3 - Type Of Contact

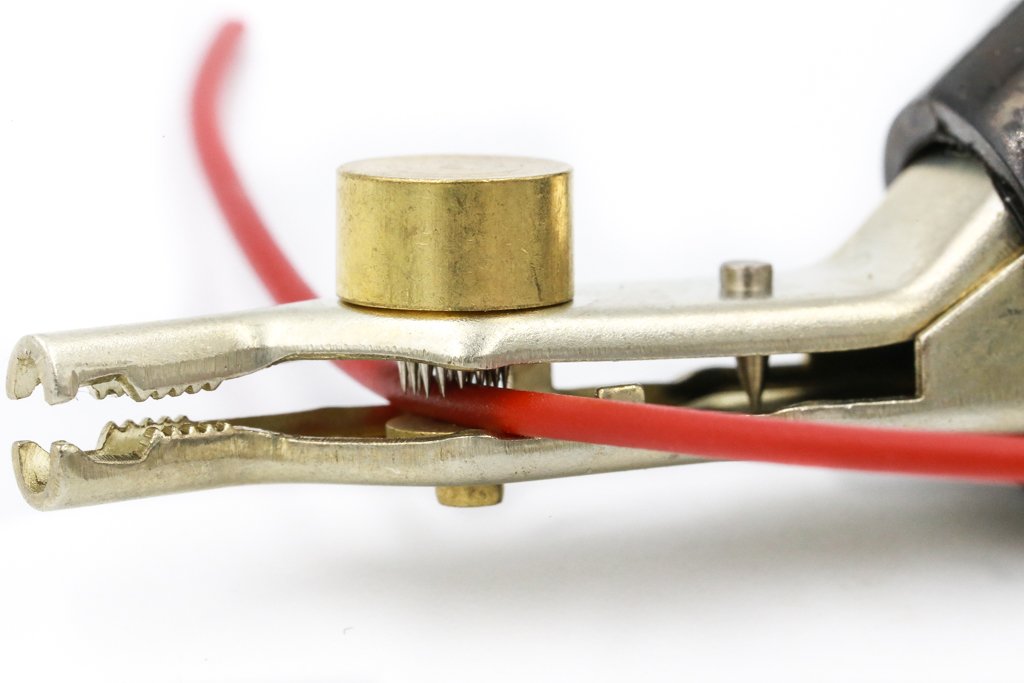

The connection reliability directly affects the insulation piercing connector performance during electrical testing. The most common contacts in use include a single needle or a set of multiple needles often known as a 'bed of nails'. The number or size of these sharpened needles that pierce the insulation directly impacts on the connection quality. The correct type of contact for your application is pivotal. Too small and the needle(s) will struggle to breach the insulation making the connection weak or intermittent resulting in misleading results. Too large and the hole made by the needle(s) won’t self-heal and conductor damage through corrosion or dirt bypassing the insulation is likely. The needle bed contact type is typically preferred on smaller gauge cables, as it's easy for a single needle to miss the internal conductor. A bed of nails increases the reliability of making a positive connection. View both contact types below;

4 - Connection Methods

Another important factor affecting the reliability of an insulation piercing clip is the connection method. Sufficient force to hold the contact interface in place is critical to ensure a strong and reliable connection for electrical testing. Connection methods typically suit different applications and those available include screw down, spring loaded and hand force. Some will combine two of the methods to maximise the likelihood of a good first time connection. Below we explore the different methods and explain their advantages and disadvantages.

Screw down Connection

Screw down insulation piercing clips are slower to install than both spring-loaded and hand force piercing connectors. Although the connection is stronger and more reliable for longer electrical testing periods. Reasonable access around the wire is needed to ensure the technician can tighten the piercing connector to make a good connection.

Advantages

- Hands-free testing

- Personal assurance the connector is tight

- Very reliable connection

- Robust

Disadvantages

- Slower installation

- Excess pressure could damage the internal wire strands

- Limited to applications where wires are accessible enough for the connection to be screwed down.

Spring Loaded Connections

Insulation piercing connectors with spring loaded connections rely on the tension of the spring sinking the needle into the insulation to create a contact. The spring is an elastic object that stores mechanical energy. The springs energy is dependant on; size, material and coil numbers. The hand-held nature of these probes often limits the maximum voltage capacity.

Advantages:

- Reliable connection

- Fast connection

- Costs effective

Disadvantages:

- Reduced working life as the spring will eventually wear resulting in a weaker connection

- Weak spring may struggle to pierce hardened insulation often found on old wires that have been subjected to heat

5 - Connection Tip

Insulation piercing connectors will have some kind of shape to the tip of the connector which is designed to assist with the positioning of the wire that is being connected to. This usually takes the form of a 'V' or 'U' shape at a radius suitable to allow wires that the connector is designed for to sit central under the needle(s). It is also possible to find tips that have extending hooks with an embedded needle to capture wires in a jaw.

It is import to choose the insulation piercing connector that is designed for the range of wire diameters that you with to use them with. It is ideal for the wire to sit central in the tip so that the needle(s) pierce the exact centre of the wire. If the tip is too large with a small diameter wire it is possible that the wire incorrectly seats in the tip and the needle(s) misses the conductor or makes a poor connection. If the connector tip is too small for a large diameter wire it is possible for the needle to push the insulation off to the side and again miss the conductor. This is especially important if the point of connection is difficult to view whilst making the connection.

'V' shaped tips are the most forgiving for a wider range of wires and the technician can assist the connection process by slightly pulling the connector onto the wire to help it centralise at the bottom of the 'V'.

6 - Conclusion: Insulation Piercing Connector

Insulation piercing connectors are useful in many applications, most commonly; automotive diagnostics; telecoms, security alarms, and decoders. There are a number of purpose-built connectors available on the market using different contact types, sizes and connection types along with differing designs of the tip to assist with wire positioning. To choose the right insulation piercing connector for your application it is recommended to use a ‘work backwards’ approach and assess what wires you plan to test. From there, identify your exact insulation piercing connector requirements by wire diameter capabilities, contact type, and connection method. Many insulation piercing connectors are serviceable in different applications, however using the right tool for the job, usually makes the task faster, safer and accurate.

Single Needle

Single Needle